Custom shoe development plays a critical role in transforming early concepts into high-quality, production-ready prototypes.

Behind every successful footwear collection lies a precise and highly technical development process. For international brands, especially in Germany and the United States, partnering with a reliable Portuguese manufacturer often means turning a creative concept into a functional, production-ready prototype.

A well-structured custom shoe development workflow improves accuracy, reduces risks and accelerates time-to-market. At LG Shoes, this process combines design, engineering and craftsmanship to ensure prototypes that meet technical, aesthetic and sustainability expectations.

This article walks through the full prototyping journey, helping decision makers understand why a solid development process is essential when choosing a private label manufacturer.

Table of contents

- What information kickstarts custom shoe development?

- How are initial designs and technical drawings created?

- How does material selection impact the first sample?

- What is the role of the last in prototype development?

- How is the first physical prototype constructed?

- How are fit testing and adjustments performed?

- When is the pre-production sample ready?

- FAQs

- Editorial Note

1. What information kickstarts custom shoe development?

The development process begins with a clear and detailed project brief. This step lays the foundation for all technical, aesthetic and structural decisions, and it helps prevent time-consuming revisions later.

A strong brief usually includes:

- target consumer and intended use

- sketches or moodboards

- outsole concept or preferred construction

- material preferences and sustainability goals

- target price range and market positioning

- sizing requirements

- comfort expectations

- performance considerations

For brands focused on responsible production, LG Shoes reinforces this stage with internal environmental standards supported by ISO 14001, ensuring that material and process planning align with sustainability claims.

A well-prepared brief dramatically reduces misunderstandings, keeps timelines accurate and aligns the development team with the brand’s vision.

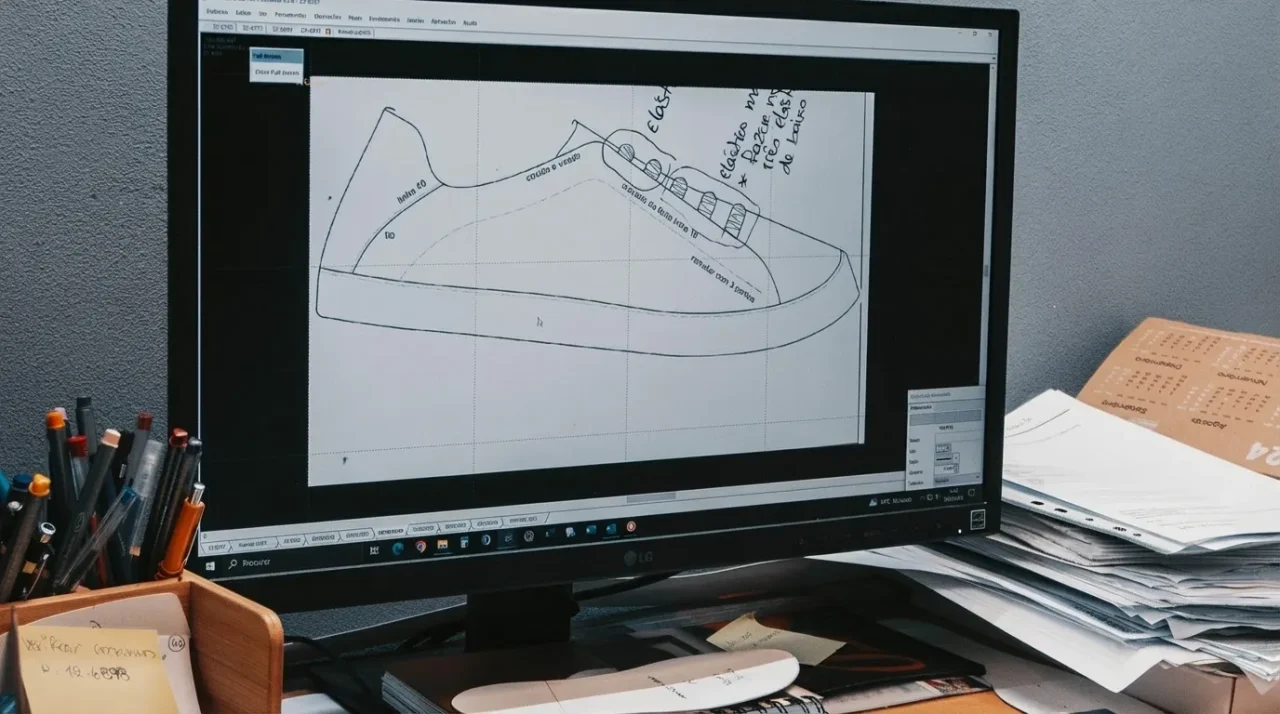

2. How are initial designs and technical drawings created?

Once the brief is approved, the development team transitions from concepts to technical structure. This is where creative vision meets engineering discipline.

Key steps include:

- detailed 2D drawings to define proportions

- refinement of pattern lines for comfort and efficiency

- identification of stitching and reinforcement points

- outsole, midsole and component specifications

- preparation of the technical file shared with all internal teams

Technical drawings must account for:

- material behavior

- lasting allowances

- stitching tension

- pattern scaling

- functional stress points

They act as the blueprint for pattern making, production planning and prototype evaluation.

For more insights into structural foundations, the LG Shoes overview of construction methods helps brands understand how different constructions influence flexibility, durability, weight and sustainability.

3. How does material selection impact the first sample?

Material selection is one of the most influential steps in custom shoe development. Every component affects performance, comfort and durability.

Key considerations include:

Performance factors

- breathability

- moisture control

- flexibility

- thermal comfort

- long-term durability

Production and sourcing factors

- MOQ

- supply chain stability

- availability of sustainable alternatives

- cost structure

Design and comfort factors

- texture

- color fastness

- softness

- stretch behavior

- resistance to deformation

During testing, development teams analyze how materials behave when stitched, lasted and flexed. Even a minor difference in leather thickness or lining density can influence:

- fit

- volume

- weight

- long-term comfort

- final silhouette

Because of this, brands often request multiple variations during early prototyping.

4. What is the role of the last in prototype development?

The shoe last provides the mechanical structure on which the entire prototype is built. It determines:

- silhouette

- toe shape

- instep volume

- heel curvature

- walking comfort

- overall fit

Brands may choose to:

- adopt a standard last

- request modifications based on their signature fit

- develop a fully custom last for premium accuracy

A well-designed last improves size grading accuracy and reduces the need for revisions, as it ensures that the prototype aligns with the brand’s comfort and aesthetic expectations.

The last impacts not only style but also biomechanics. It influences how pressure is distributed across the foot, how the shoe flexes and how stable it feels during movement.

5. How is the first physical prototype constructed?

Once drawings, materials and the last are approved, the first prototype is constructed. This step brings together craftsmanship, mechanical understanding and technical consistency.

The process includes:

- cutting all patterns according to the technical blueprint

- stitching the upper, including reinforcements and structural elements

- lasting the upper over the last

- adjusting tension for comfort and shape accuracy

- applying the chosen construction method

- attaching the outsole

- performing finishing, trimming and quality checks

Each construction method influences how the shoe behaves. At LG Shoes, methods such as Strobel, San Crispino and Montado are selected based on:

- flexibility goals

- durability requirements

- sustainability considerations

- target consumer expectations

The first prototype provides the brand with a real, functional representation of the design. It is where proportions, comfort, structure and material interaction become fully visible.

6. How are fit testing and adjustments performed?

Fit testing ensures the shoe performs as intended in real use. It helps identify:

- heel slip

- toe room issues

- pressure points

- insufficient or excessive flexibility

- lining discomfort

- imbalance

The team may conduct wear tests, flex tests and targeted pressure evaluations.

Adjustments include:

- pattern corrections

- component repositioning

- foam or lining modifications

- adding or reducing reinforcement

- outsole or midsole adjustments

- upper material refinements

These changes are essential for ensuring comfort, functionality and long-term performance.

A well-executed fit testing stage prevents expensive corrections during production.

7. When is the pre-production sample ready?

After implementing all revisions, the pre-production sample (PPS) is created. The PPS is:

- the final reference for mass production

- a proof of construction accuracy

- a validation of materials and comfort

- a demonstration of consistency with brand requirements

It undergoes internal quality checks to verify:

- stitching precision

- outsole alignment

- durability of reinforcements

- correctness of pattern scaling

- overall construction integrity

For additional industry insights and standards, brands can explore APICCAPS.

A well-prepared PPS reduces production risks and ensures reliable private label manufacturing.

FAQs

What is the typical timeline for developing a footwear prototype?

Most prototypes take between 2 and 6 weeks depending on complexity and material availability.

How many revisions are normal?

Projects typically require between 1 and 3 iterations before approval.

Does prototyping include sustainability checks?

Yes, particularly when working with certified manufacturers under ISO 14001.

Can brands request multiple prototypes?

Yes, especially to compare different materials, constructions or comfort solutions.

Editorial Note

This article was written by the LG Shoes communication team in collaboration with the product development department. It aims to support international brands seeking reliable insights into footwear prototyping and custom shoe development. All information reflects LG Shoes expertise as a Portuguese shoe manufacturer specializing in private label production and sustainable development workflows.